dwell time in vickers hardness test|vickers hardness testing procedure : traders 30 .dwell time to test force outside recommended duration, in this case: 30 seconds. Find an explanation of how to read a Vickers hardness value (e.g. “640 HV30”), and of the meaning of . 6 de abr. de 2022 · Um pouco de terror. The Baby estreia dia 24 de abril na HBO e na HBO Max.Inscreva-se no nosso canal! 👉 https://bit.ly/2Qek1HbSiga:🖤 https://www.tiktok.com/.

{plog:ftitle_list}

Resultado da A MORENA CAVALA GOSTOSA CHEGOU E MOSTROU TODO O SEU TALENTO NA HORA DE FUDER COMMA GOZOU GOSTOSO NA .

vickers hardness values explained

The test force is held for a specified dwell time and then removed. Step 2 - For the Vickers hardness test, the lengths of the two diagonals are measured and the mean diagonal length .Apply the specified load (e.g., 3000 kgf) for a defined dwell time (e.g., 15 seconds). 3. Measure the diameter of the indentation using a calibrated microscope. 4. Calculate the Brinell .

project report on spring testing machine

30 .dwell time to test force outside recommended duration, in this case: 30 seconds. Find an explanation of how to read a Vickers hardness value (e.g. “640 HV30”), and of the meaning of .Our advanced Macro Vickers hardness tester 3842 is a state-of-the-art, precise testing system suitable for hardness analysis of metallic specimens in metallography laboratories or .Vickers hardness number (VHN) can be found directly from the Vickers hardness testing machine. In that machine, first an indent was made on the surface of the specimen by applying force of .

What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. The Rockwell hardness test is less affected by surface rough .

The Vickers hardness test estimates the indentation hardness for a fractional part of metal, composites, or ceramic materials. In essence, the hardness of a material is its potential to present material with structural integrity and .The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen. Due to the need to conduct optical indent evaluation, Vickers hardness testers must be equipped with an optical system, .Vickers Hardness Testing Knoop Hardness Testing Case Depth Hardness Testing . This major load is then released, returning to the preliminary load. After holding the preliminary test force for a specified dwell time, the final .

Vickers hardness testing uses a pyramidal indenter and a load-on, load-off procedure, which gives geometrically similar impressions regardless of the penetration depth. . However, this study only chose a single set of testing parameters with a load of 1 g and a dwell time of 30 s for Vickers hardness testing. In order to analyse polymers for .If the load is applied for more than 15 seconds, the dwell time should be indicated following the ISO 6507 standards. . The Vickers hardness test is a common, widely used method for measuring the hardness of materials. It is an excellent method when testing softer materials that could not withstand the forces required by other standards such .The Vickers hardness test method, otherwise called a microhardness test method, is used for small objects, thin sections, as well as the case depth work. . The load when applied to the test sample pushes through the test sample and is allowed a dwell time of 10-15 seconds. When dwell time elapses, the load is removed, and the indenter is also .Introduction to Vickers Hardness Test The Vickers hardness test, developed in 1921 by Robert L. Smith and George E. Sandland of Vickers Ltd., provides an alternative to the Brinell hardness test with a simpler scale. . After a dwell time, the load is removed, and the indentation size is optically evaluated using a specific equation to .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness Testing Considerations The following sample characteristics should be considered prior to selecting the hardness testing method to use: • Sample Size • Cylindrical Samples • Sample ThicknessHigh Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the The Vickers Hardness Test involves pressing a pyramid-shaped indenter with a precisely known load into the material's surface. The indenter typically has an angle of 136 degrees between opposite faces. . Load and Dwell Time: Apply the desired load (typically less than 1 kgf) and allow it to dwell on the material surface for a specific time.

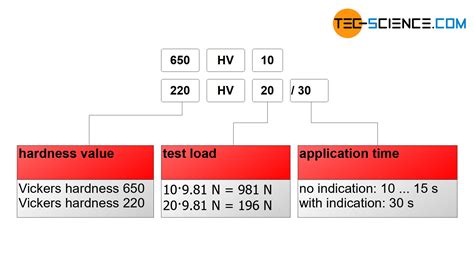

All information about the Vickers hardness test Test procedure Sample request for the Vickers method Vickers hardness Hardness Discover now. . The test cycle takes somewhere between 30 and 60 seconds, not including the time taken to prepare the specimen. Due to the need to conduct optical indent evaluation, Vickers hardness testers must be . Finally, to show the usefulness of the Vickers micro-hardness testing method, the calibrated test method was applied on iPP with additions of carbon black up to 3 wt.%. . However, this study only chose a single set of testing parameters with a load of 1 g and a dwell time of 30 s for Vickers hardness testing. In order to analyse polymers for .Generally, the dwell time for the test force is 10 to 15 seconds (nominal time duration 14 s). If the dwell time is any longer, the duration in seconds must also be specified in the hardness value .

with a load of 1 g and a dwell time of 30 s for Vickers hardness testing. In order to analyse polymers for hardness testing, much care and attention must be given to the sample preparation using .🕑 Reading time: 1 minute. The Vickers hardness test is a static hardness test method, used for both macro and microhardness testing. It is an optical method of testing where the size of the indentation left by the indenter is measured to determine the hardness value of a test specimen.The Vickers hardness testing standards specify a specific distance between multiple indentations in order to prevent errors in interpreting perceived hardness. These are the standard dimensions of NextGen's Vickers .Generally, the dwell time for the test load is 10 to 15 seconds (s). If the dwell time is any longer, the duration in seconds must also be specified in the hardness value, e.g.: 210 HBW 5/250/30 (dwell time of 30 s).

Vickers Hardness Testing Protocol: The Vickers hardness test was conducted using a microhardness tester with a diamond pyramid indenter (HM123) (Mitutoyo Corp, Aurora, IL, USA) with a 50 g load and a 15 s dwell . The Knoop hardness test is very similar to the Vickers hardness test in that a diamond/pyramid shaped indenter is applied to the test material for a specific dwell time. However, the Knoop indenter is an elongated diamond, thus allowing it to test brittle materials and thin layers without cracking.Wilson VH3300 vickers and knoop hardness tester provides a fully integrated platform for your complete Vickers and Knoop hardness testing needs. . Dwell Time 1 - 999 seconds Standard Compliance ASTM E384, E92; ISO 6507, 9385, 4545 Magnification Range 30X - 2000X with digital zooming .The test force is held for a specified dwell time and then removed. For the Vickers hardness test, the lengths of the two diagonals are measured and the mean diagonal length is calculated, which is used to derive the Vickers hardness value.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The length of time the indenter is in the material; The indenter geometry; The geometry of the workpiece; . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.

Vickers hardness testing is extensively used in the metals and alloys industry to evaluate different metallic materials' hardness, strength, and durability. This instrument helps evaluate metallic components' hardness, strength, and durability, ensuring they meet the required specifications and standards. . Inquire about their service and . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

Overview of hardness testing methods 4 3. Low-load & micro hardness testing machines − the DuraScan Series 6 4. Universal hardness testing machines − the DuraVision Series 8 5. DuraJet Rockwell hardness testing machine – flexible & versatile 10 6. ZHR Rockwell hardness tester 12 7. ecos™ III – The most efficient hardness testing .These methods of hardness testing are valuable tools in determining “shallow layer hardness,” such as surface hardness, coating hardness, and case depth. . considering ASTM E384 standard dwell time of 15 seconds. This is part of the “slow” problem mentioned previously. . Recording and converting results from microns to Vickers or .The two letters "HV", standing for "Hardness according to Vickers" The applied test load in kgf; According to ISO 6507: The dwell time of the test load, but only if this is not between 10 and 15 seconds (uncommon in practice) Examples. 640 HV30. 640 .hardness value; HV .as per Vickers; 30 .with test load of 30 kgf (or test force of 294.2 N )

vickers hardness testing time

vickers hardness testing procedure

spring machine operator

vickers hardness testing distances

About this game. arrow_forward. Casumo is the multi award-winning online casino where anyone can play. Discover 2,000+ casino games .

dwell time in vickers hardness test|vickers hardness testing procedure